TECHNICAL OVERVIEW

The system’s design is based on the “new Austrian tunnelling method” (which makes use of the bedrock located a few metres from the tunnel to stabilise the rock closer to the structure).

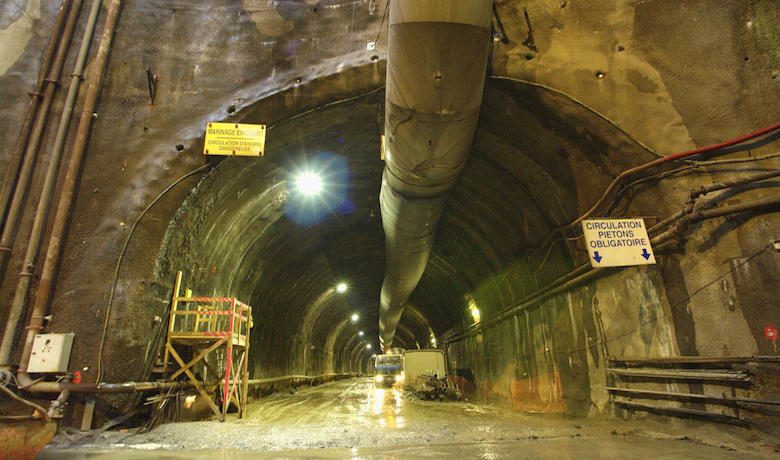

The tunnel was excavated by partial sections (cap, bench, invert) except in Visean limestone and the more accommodating soil of Westphalia, where the full-face excavation method was used. One of the major difficulties in this project was getting through the Magnée fault, separating two distinct rheological entities characterised by brittle and ductile behaviour. The ground contained dislodged and heavily faulted rock stretching across several dozen metres. Excavation, launched with a rockhead TBM at the project manager’s request was completed at the consortium’s initiative using blasting technique to the full satisfaction of all participants. The rockhead TBM was used on four occasions: twice from the ends and twice from a central shaft some 50 metres in diameter excavated from the surface.

The final structure consists of an outer retaining hull designed to provide additional support to the bedrock. It is made of fibre-reinforced shotcrete, bolts, and steel arches.

Specific techniques (umbrella-arch method, protection bars and panels, tie-beams and injection) were used for unstable ground (faults, karst, mining galleries, mined coal seams). A drainage and sealing system was installed, consisting of a honeycombed draining membrane, a geotextile, and a PVC membrane linked to the water-evacuation system placed in the foundation slab. It is designed to prevent any increase in hydrostatic pressure in proximity to the tunnel.

The inner hull, made from cast concrete, is 30 centimetres thick. It is designed to support additional processes (caulking in the drainage system) and enable implementation of various systems (electrical, fire extinguishors).