background

With a will to integrate member states economically through the “Single Market,” the European Union decided to develop its transport infrastructure to facilitate travel between neighbouring countries. It focused on rail transport as the main means for travel.

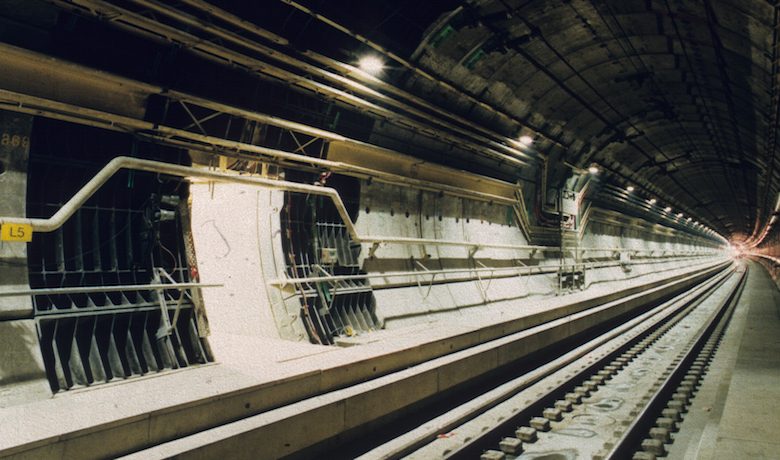

The construction of the Channel Tunnel was part of a major European program to create a high-speed rail network in continental Europe.

The English Channel, which once shielded the British Isles from continental Europe, now enables this rail link connecting France and England.

The idea of connecting the United Kingdom to the continent was the dream of engineers for many decades. Officially inaugurated by Queen Elizabeth and French President François Mitterrand on May 6, 1994, the Channel Tunnel became a reality.