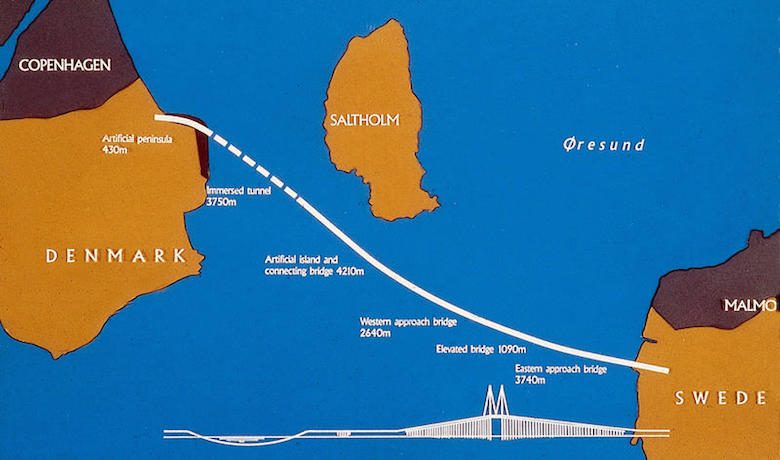

BACKGROUND

Øresund is the name of the strait that separates Denmark from Sweden. The project of building a permanent link between these two countries aimed to make the strait a hub for visitors from western Europe travelling to Sweden, Norway, and Finland. It all began in 2000, the fixed link crossing the Sund was inaugurated or rather, over a century ago, when some people were already envisioning bringing these 2 enemy regions together as part of a strategic alliance. In earlier times, ferries made the crossing, following 2 itineraries: the Storebælt crossing to get to the island of Sjælland (Copenhagen) and the Øresund crossing to get to Sweden. The project was designed to replace the ferries with a set of bridges and tunnels providing direct road and rail access.

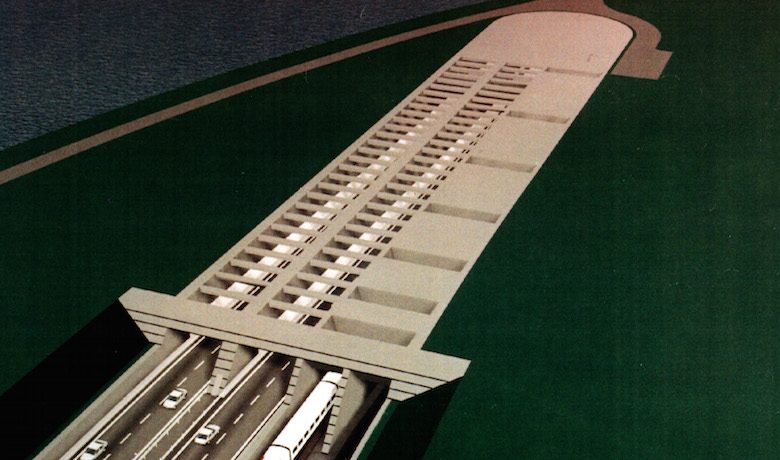

The suspended bridge connects the city of Malmö to the artificial island of Peberholm. At one end of the island, roads and rail run under a channel into the tunnel that leads to Copenhagen.