IMPACT

Liquefied natural gas from the tanks, when converted into gas again, is supplied to consumers and electricity producers in Baja California and Southern California. It meets all the quality standards of Mexican pipelines and US gas.

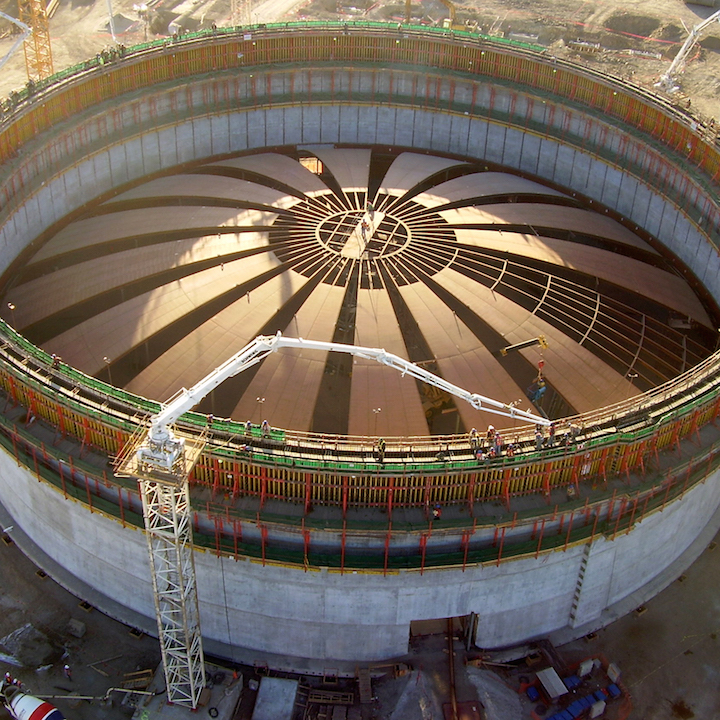

VINCI Construction Grands Projets has been present in the LNG tank construction market for more than 40 years with many projects across the world, often in extreme conditions. Extreme cold, such as the Yamal project and extreme heat, such as the Ras Laffan and Wheatstone projects.

These tanks are not only economic development factors, but also optimise the storage of liquefied natural gas, a non-polluting energy source of which the world has higher reserves than petrol.

To design such reliable tanks for each project, all the designing as well as general and specific tasks are handled by experienced internal resources. Our design-build methods integrate safety measures right from the engineering phase. Our engineers are involved in all the stages, so each project is always designed with the construction in mind.