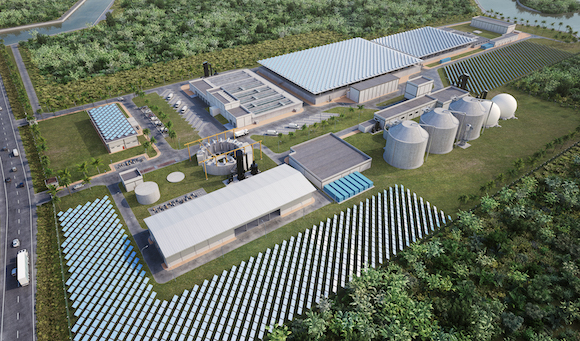

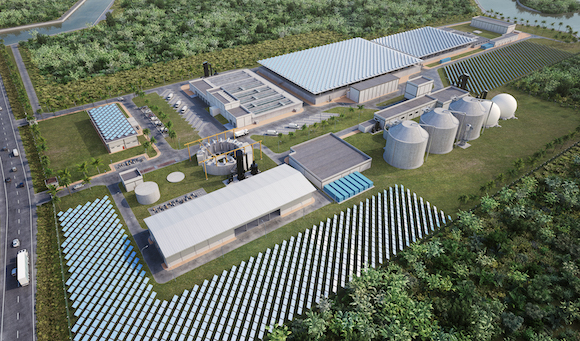

On 14 November 2019, VINCI Construction Grands Projets signed a contract with the Phnom Penh Water Supply Authority to design and build the Bakheng water treatment plant in the northern outskirts of the Cambodian capital.

The first phase of the project, with a value of $155 million (€141 million), covers construction of:

- a first treatment line with a capacity of 195,000 cu. metres per day,

- the intake in the Mekong River with a capacity of 390,000 cu. metres per day,

- two 1.4 metre diameter pipelines with a length of 1.5 km to carry water from the Mekong to the treatment plant,

- a 2 metre diameter pipeline with a length of 7.8 km (including a 630 metre river crossing to be built using a microtunneling machine) to bring drinking water to more than 500,000 inhabitants of the capital city.

To minimise the plant’s carbon footprint, its electricity requirements will be partly supplied by 27,000 sq. metres of solar panels with 3.8 MW installed capacity.

The project, co-financed by the French Development Agency, the European Investment Bank and the Phnom Penh Water Supply Authority, will employ more than 500 local workers and supervisory personnel at the height of activity.

The contract provides for a second conditional works phase with a value of $45 million (€41 million). This phase is designed to double the plant’s treatment capacity to 390,000 cu. metres per day. Following handover of the second phase, the project will provide drinking water for a population of one million.

The new project confirms VINCI Construction Grands Projets’ commitment to expanding drinking water access in Cambodia. In 2017, the company handed over the Niroth drinking water plant on the outskirts of Phnom Penh and the wastewater treatment plants at the Phnom Penh and Siem Reap airports. This year, the VINCI Construction Grands Projets hydraulic engineering teams also delivered two drinking water plants in Siem Reap and Chamkar Mon (in the centre of the Cambodian capital).

Since it was founded in 2000, VINCI Construction Grands Projets has built water projects that supply six million people with drinking water and treat wastewater for a population equivalent of 2.5 million around the world.

ITER Organization, the international organisation set up in November 2006 to operate and subsequently dismantle the ITER facility; Fusion For Energy (F4E), the European Union organisation responsible for the European contribution to the ITER programme; and Groupe VINCI, leader of the consortium1 in charge of constructing the main buildings at the site, today announced the completion of civil engineering works on the ITER Tokamak2 Building at the Saint Paul lez Durance/Cadarache site in south-eastern France. This major project milestone was symbolically reached with the final concrete pour, on 7 November 2019, of the upper part of the building in which the ITER Tokamak will soon be assembled.

With the on-time completion of the Tokamak Building civil engineering works, the metal frame of the roof can be installed and the ambitious First Plasma3 target in 2025 maintained.

The civil engineering project, which got under way in 2010, called for exceptional complex project management capabilities and cutting-edge expertise.

The teams working within the VINCI-led consortium set up an efficient and agile project organisation enabling them to integrate all design changes requested by the ITER scientific teams as construction proceeded. The mobilisation of the VINCI design and works teams, the use of cutting-edge digital design tools and the complex project management expertise of the VINCI teams made this successful system possible.

The construction of the 73 metre high, 120 metre wide Tokamak Building also required production of highly specific concretes. The worksite teams developed about 10 formulations, some of which have unique features enabling them to shield workers and the environment from fusion-generated radiation. Some parts of the Tokamak Building also called for steel reinforcement density rarely used on projects on this scale (up to 10 times the density of an apartment building wall). Lastly, access to the heart of the Tokamak Building required customised production of 46 heavy nuclear doors. Each 70-tonne door is manufactured in Germany, brought to the site, filled with concrete and assembled in the heart of the Tokamak Building.

“In deciding to take part in the leading construction of the particularly complex ITER buildings, VINCI undertook to help write a new chapter in one of the most ambitious and promising research programmes ever undertaken – a programme designed to reproduce on Earth the reactions that have been taking place in the heart of the Sun and stars for billions of years. Its goal is to harness hydrogen fusion and thereby pave the way for a new era for all humanity by making available a massive source of energy that can be varied at will, is intrinsically safe and has no impact on the climate and the environment. This was a huge challenge to which the men and women at VINCI have been tenaciously and resourcefully rising for nearly a decade. We want to warmly thank Vinci for having been a highly capable, reliable partner sharing our objectives, our standards and our determination. The success of ITER will be theirs.” said Bernard Bigot, Director-General of ITER Organization.

“We are pleased to announce the completion, following a lengthy and complex process, of the civil engineering works for the main building that will house the ITER Tokamak, the world’s largest fusion machine. Europe is the party responsible for building the infrastructure of this extremely ambitious programme. Our close collaboration with VINCI, its partners and more than 700 workers has enabled us to successfully finalise this stage of the project in compliance with the safety, security and quality requirements.” said Laurent Schmieder (F4E), who oversees the team in charge of building construction and electrical systems for the ITER project.

“VINCI Construction and its partners Razel-Bec and Ferrovial are extremely proud of having carried out the ITER civil engineering works. ITER is a one-of-a-kind research programme in terms of its complexity, precision and size. It is an extraordinary human undertaking, but also a huge technical challenge, and we were constantly called on to innovate and expand our expertise. With ITER, we are humbly helping to implement one of the greatest and most ambitious energy projects of our time, designed to make electricity available throughout the world without CO2 emissions or radiological risk. For us, as a builder, it is a matter of great pride to have laid the cornerstone of a structure of such importance to humanity.” said Jérôme Stubler, Chairman of VINCI Construction.

1The consortium in charge of construction of the main ITER buildings is led by VINCI via its subsidiaries VINCI Construction Grands Projets, VINCI Construction France and Dodin Campenon Bernard. It also includes the Ferrovial (Spain) and Razel-Bec (France) companies. The heavy nuclear doors were designed and produced by a VINCI Énergies subsidiary, Cegelec, in partnership with Sommer (Germany).

2A tokamak is an experimental machine designed to exploit fusion energy. In a tokamak, three conditions must be met to obtain a fusion reaction: very high temperature (about 150 million degrees Celsius); sufficient particle density to produce a very large number of possible collisions; and sufficiently long energy confinement time to ensure that the collisions occur at the highest possible speed. Tokamak is a Russian acronym standing for “toroidal chamber with magnetic coils”.

3The plasma, the fourth state of matter, is achieved when a gas is raised to a very high temperature, dissociating electrons and nuclei. In this medium, hydrogen nuclei can fuse and release energy.

The joint venture will be responsible for the final design, construction and commissioning of Old Oak Common station in North West London, delivering six underground platforms as well as up to eight platforms on the adjacent Great Western Main Line.

Balfour Beatty’s in-depth expertise of constructing critical major transport terminals across the world will combine with VINCI’s knowledge in constructing high speed lines and UK rail infrastructure projects, and SYSTRA’s expertise in designing, integrating and project managing transport systems.

On completion, Old Oak Common station will become the UK’s best-connected station, providing direct services to three major airports, eight of Britain’s ten largest cities and forming part of one of Britain’s largest regeneration projects which will help create up to 65,000 jobs and 25,000 new homes in West London while also dramatically increasing rail capacity across the UK.

Nigel Russell, Project Director for the Balfour Beatty VINCI SYSTRA joint venture said: “This award reflects the combined strength of our joint venture and recognises our world-class capabilities in designing, managing and delivering complex infrastructure projects.

“We look forward to applying our expertise to deliver this critical piece of national infrastructure so essential to driving the skills agenda, to the rebalancing of the UK economy and to the enabling of a resilient and competitive construction and infrastructure industry.”

At construction peak the project will employ a direct management team of 140 and a wider workforce of approximately 2,500.

This latest contract award follows Balfour Beatty VINCI’s appointment in 2017 to deliver Lot N1 and Lot N2 of HS2’s main civil engineering works package in a two-part design and build contract, valued at c. £2.5 billion.

On Friday, 2 August 2019, Panamanian President, Laurentino Cortizo, and Panama Canal Administrator, Jorge Quijano, unveiled the Atlantic Bridge in Colón, Panama. This exceptional 4.6 km structure, including 3.1 km of exceptional engineering structures, located 3 km north of the Gatun and Agua Clara locks, creates a new link between the North American and South American continents that can be used whether the canal locks are in operation or not.

Due to the adversity of the Panamanian tropical climate on the Atlantic side, a technical solution entirely made of reinforced concrete was chosen by the Panama Canal Authority rather than a metal structure. The central span (the bridge section that spans the canal), consisting of 530 metres of concrete deck located 75 metres above sea level, constitutes a world record for a cable-stayed bridge, while its two towers dominate the waters of the Atlantic Ocean at over 210 metres high. The foundations of these towers, anchored in highly unstable ground subject to potentially major seismic disturbances, posed a veritable challenge.

In order for work to be carried out without interrupting the transit of container ships, four innovative form travellers, each weighing 240 tonnes, were used to build the central span.

Thanks to a strong and shared safety culture during the design and construction of this unique engineering structure, it was completed without any serious accidents.

The construction of this bridge relied heavily on the Group’s expertise in synergy: VINCI Construction Grands Projets built the infrastructure, Rodio Swissboring Panamá, subsidiary of Soletanche Bachy, created the deep foundations and Freyssinet installed the stays.

The Link Alliance, which includes VINCI Construction subsidiaries VINCI Construction Grands Projets (main contractor) and Soletanche Bachy International, along with their partner Downer and designers Aecom, WSP-Opus, and Tonkin & Taylor, has today signed the Design-Construction Alliance contract for Package 3 of the City Rail Link project in New Zealand.

The contract, worth 1,658 million New Zealand dollars or approximately 970 million euros, is for the design and construction of 3.45 km of extension of a train line, including 3.2 km of tunnel, to link the existing Britomart station to the existing Mount Eden station. Along that line, three new stations will be built, two of which are underground. The tunnels will be made using an earth pressure tunnel boring machine with a diameter of 7.18 m.

The signed contract is an “Alliance” type, meaning the designer-constructor consortium and the client, City Rail Link Limited, can create a single and integrated team to deliver the project to Auckland residents in 2024.

For a total cost of 4.419 billion New Zealand dollars, or 2.586 billion euros, the City Rail Link project is expected to double the number of people who can reach downtown Auckland in under 30 minutes. This new train line has been designed to accommodate 54,000 passengers per hour at peak travel times, which is the equivalent of two double four-lane motorways.

With this contract, VINCI Construction once again demonstrates its ability to support urban centres in designing and constructing large urban mobility and public transport projects, as it does in France, Hong Kong, Singapore, Doha, and more recently, Virginia (USA), and Ottawa (Canada), with the design-construction contract for the LRT.

VINCI Construction Grands Projets and Bouygues Travaux Publics, partners in the NOVARKA consortium, symbolically handed over the key to the Chernobyl New Safe Confinement to the Ukrainian authorities at a ceremony that was held on site on Wednesday 10 July, in the presence of the Ukrainian President, Volodymyr Zelensky.

The delivery of this project marks the end of an outstanding and exceptional building site that lasted for 12 years and was conducted under unique conditions, with more than 10,000 workers and technicians of NOVARKA putting in a total of 33 million working hours to complete the construction of the New Safe Confinement for the damaged reactor no. 4. The rigorous execution and the innovative methods that were implemented enabled this project to come to fruition without any major work accident or radiological incident.

The Chernobyl arch is the largest moveable land-based structure ever built, with a span of 257 metres, a length of 162 metres, a height of 108 metres and a total weight of 36,000 tonnes equipped. It will make the accident site safe and with a lifetime of 100 years allow for the future dismantling of the ageing makeshift shelter from 1986 and the management of the radioactive waste.

This project was made possible thanks to financing spearheaded by the EBRD, thanks to the Project Management of Bechtel and thanks to the day-to-day backing of the client, the Chernobyl Nuclear Power Plant (ChNPP).

“Remember, back in 1992, we had to work out how to do everything from scratch…”, declared Patrick Kadri, Chairman of VINCI Construction Grands Projets. “We faced a blank sheet and had just won a conceptual competition. It took a lot of audacity, vision, and a fair amount of madness to embark on this project! The challenges were monumental: to design a state-of-the-art prototype in an extremely constraining environment, constantly pushing against the limits of know-how, striving to secure the cooperation and endorsement of all the stakeholders worldwide, inventing materials that did not exist and unique construction methods. This project occupied a major part of our working lives. And we are all aware of the environmental progress that this achievement represents for Ukraine, its neighbouring countries and the whole of Europe.”

“One doesn’t get a chance to be involved in two building sites like that one in one’s career”, said Marc Adler, Deputy Chief Executive Officer of Bouygues Travaux Publics. “Because it was huge, because it was complicated, because Europe and the whole world had bet a lot on our success. Each of our trades really went into overdrive and surpassed themselves: the engineers, the radiation protection people, the employees in charge of executing the work, the project managers…not to mention the people in charge of human resources, who recruited staff in more than 30 countries. Chernobyl will be known in the history of civil engineering as a concentrate of innovation, and the engineers who took part in this project are already transmitting the teachings of this outstanding endeavour in engineering schools.”

The acceptance of the project by the ChNPP heralds a new era in the history of Chernobyl, that of the dismantling of the damaged facilities, made possible by the demolition equipment integrated within the arch and controlled remotely. A life size trial was conducted successfully on 25 April 2019. The arch was designed to last for 100 years.

The city of Ottawa has selected East West Connectors, a joint venture led by Kiewit (60%) and VINCI (40%) through its subsidiaries Eurovia, VINCI Construction Grands Projets and Dodin Campenon Bernard, to build the extension to the Confederation Line, one of the two lines in Stage 2 of Ottawa’s O-Train light rail transit (LRT) system.

The contract, worth €1.7 billion, covers design, construction and financing of 27.5 km of infrastructure to extend the Confederation Line to the west and east. Drawing on the expertise of the various entities, VINCI, in a joint venture with Kiewit, will build 4 km of cut-and-cover tunnels, 20 engineering structures, 16 stations and a maintenance centre. It will also undertake localized widening of 12 km of motorway to permit LRT system construction and provide the associated systems such as the power supply, supervision and voice-data-image system, signalling and train control system.

In addition to the Confederation Line extension, Stage 2 of the Ottawa O-Train includes extending the Trillium Line to the north and south. When Stage 2 is brought into service in 2025, the O-Train LRT will stretch over almost 64 km and have 41 stations. It will provide rapid and reliable rail service to nearly 80% of Ottawa’s population and carry up to 48,000 one-way passengers a day during peak periods.

The consortium consisting of VINCI Construction Grands Projets (50% share and lead contractor) and Acciona Agua S.A. (50%) won the contract for the design-build portion of phase 1 for the Nhieu Loc-Thi Nghe wastewater treatment plant, in Ho Chi Minh City. The design-build portion of the contract is set to take five years for completion, including the starting-up process and acceptance of works. The project also calls for operating and maintaining the facility for a five-year period.

This wastewater treatment plant project, which is financed by the World Bank, is worth €200 million (€170 million for the design-build portion and €30 million for operation and maintenance). With a peak capacity of 34,000 cubic metres per hour, it will include a pumping station, biological treatment, disinfection, sludge treatment, odour treatment as well as connection to the city’s sewage system.

The plant, which will treat wastewater from the Nhieu Loc-Thi Nghe Basin, will be an essential part of Ho Chi Minh City’s second environmental plan and will benefit more than a million residents.

The project will include the hiring of up to 800 local labourers at peak periods. Also, nearly 25,000 hours of training are planned to ensure everyone’s safety at the worksite as well as the completed structure’s quality at delivery.

This new contract bolsters VINCI Construction’s presence in Vietnam, where the Group, through its subsidiaries VINCI Construction Grands Projets and Bessac, Soletanche Freyssinet’s subsidiary specialized in microtunnelling, is currently carrying out a design-build project for a 10-kilometre treated-water transfer pipeline that will supply drinking water to the centre of Ho Chi Minh City.

VINCI Construction Grands Projets has provided support to Vietnam on numerous sanitation projects in the cities of Thai Nguyen and Hoi An in 2016, Vung Tau in 2013, and Ha Dong in 2008.

The global union federation BWI (Building and Wood Workers’ International) conducted the first on-site audit of the operations of QDVC (a Qatari company owned by Qatari Diar Real Estate Investments Company and VINCI Construction Grands Projets) in Qatar on 8 and 9 January 2019, accompanied by French trade union representatives (CGT, CFDT and CFE/CGC) from VINCI. This joint audit followed the agreement on workers’ rights signed in 2017 between BWI, VINCI and QDVC at the International Labour Organisation (ILO) headquarters in Geneva.

The audit was conducted at QDVC’s main project, the Lusail Light Railway Transit System (LRT), and at the workers’ accommodation.

- It included interviews with workers on site, workers’ representatives and safety champions without management supervision;

- On the second day, the ILO Project Office in Qatar and the Qatari Ministry of Administrative Development, Labour and Social Affairs (ADLSA) took part in a presentation of the ongoing pilot project between QDVC, the ILO and ADLASA, which aims to ensure the fair recruitment of workers hired in Bangladesh for Qatar by QDVC’s recruitment and placement agencies.

The audit covered recruitment and employment practices, health and safety, working conditions, accommodation and grievance mechanisms for all QDVC workers, including subcontractors and manpower providers.

The findings of the audit emphasise QDVC’s fair recruitment and employment practices, the good level of health and safety observed at its sites, the safeguarding of workers’ rights and also proactive initiatives such as:

- the Incident and Injury Free (IIF) safety programme;

- the “buddy peer-support program” to prevent psycho-social risks;

- the grievance mechanisms for employees and subcontractors.

The audit also noted that workers are paid above the minimum wage and are satisfied with their overall conditions. The main concern that they voice is the fear of unemployment due to the lack of commercial prospects matching QDVC’s business model.

The auditors were able to attend the election of QDVC’s Workers’ Welfare Committee (WWC) and noted that the ballot and the counting of votes were carried out properly.

· A month before the audit, 31 candidates campaigned to be elected to the WWC. The level of participation in the election was 84% (and increase of 12 points compared to the previous election), with 879 out of a total workforce of 1,047 casting their votes.

QDVC had previously organized elections for its WWC in 2016, but this was the first time that an independent third party was able to observe and assess the process.

BWI and the French unions participating in the audit suggested areas for improvement including:

- providing WWC representatives with more time off to consult with other workers;

- introducing better integration of the existing grievance mechanism and the WWC;

- encouraging more detailed analysis of non-work-related accidents.

Following the audit, QDVC undertook to follow up the BWI recommendations, to continue with the training of the newly elected workers’ representatives and to increase collaboration in the area of fair recruitment of workers. The full audit report can be consulted at: www.vinci.com/publi/vinci/2019-01-BWI-QDVC-VINCI-Joint-Audit-Report-En.pdf.

The Minister of Environment of the Brussels-Capital Region, Céline Fremault, has opened the Brussels South wastewater treatment plant today. The plant includes Europe’s second-largest ultrafiltration membrane surface, put into service by VINCI Construction Grands Projets. This project, which has thus concluded a second major upgrading phase, is carried out by a consortium consisting of VINCI Construction Grands Projets, CFE, and Nizet Entreprise on behalf of the city’s water-management authority, Société Bruxelloise de Gestion de l’Eau.

From now on, a quarter of the wastewater produced in Brussels Region, which is equivalent to the volume consumed by 360,000 residents, will be treated using a high-performance process that can filter bacteriological waste and re-use water in sprinkling and irrigation systems.

This new ultrafiltration system, implemented by VINCI Construction Grands Projets, comes into play in the final stage of treated water and sludge separation thanks to the deployment of a 226,000-square-metre filtration surface. The process is preceded by advanced primary treatment stages (implemented during the first upgrading phase) using fine-screening settings of 6 millimetres and 1 millimetre and lamellar settling. It provides biological treatment of water to eliminate nitrogen and phosphorus in mixing and aeration basins 30,000 cubic metres in volume and 15 metres in depth. In rainy weather conditions, primary treatment can handle up to 5 cubic metres per second, with ultrafiltration membrane capacity approaching 2 cubic metres per second.

This technology, which combines peak performance (currently a pinnacle in the wastewater treatment sector) and compactness (226,000 square metres of membranes installed on a 1,500-square-metre surface), provides considerable benefits to projects with severe space constraints. That is the case at the Brussels South wastewater treatment plant, whose current site is cramped and packed with multiple structures in a busy urban setting.

Yet another constraint is having to maintain operations at the plant during the entire duration of the project in accordance with a highly precise and demanding task-sequencing schedule. Upon entry into service, each new project phase is operated by the consortium, with VINCI Construction Grands Projets providing close monitoring of the process’s development. This overview phase for the new ultrafiltration complex will last two years.

A new and final project stage will be launched in early 2019 with the construction of digestion (or methanisation) structures to handle sludge resulting from water treatment and of structures dedicated to the re-use of produced biogas for heat and electrical power generation as a means of limiting the new Brussels South wastewater treatment plant’s environmental impact.

Brussels South is the tenth membrane-treatment project implemented by VINCI Construction Grands Projets. Its scope and complexity, however, pave the way for new developments in other large cities striving to preserve resources and their reception environments.