- Upgrade and extension of wastewater treatment facilities

- Increase total plant capacity

- A design-build contract worth AUD $385 million (€236 million)

Icon Water, the Australian Capital Territory‘s supplier of water and wastewater services, has awarded Seymour Whyte and VINCI Construction Grands Projets – both VINCI Construction subsidiaries – the contract to upgrade and extend the existing Lower Molonglo Water Quality Control Center. This is the largest Australian inland wastewater treatment infrastructure which has been in operation since the late 1970s in Canberra.

On this 385 million AUD (€236 million) contract, the joint venture will work in a collaborative design and build approach – alongside the engineering firm BECA HunterH2O – to construct a new wastewater to increase the existing plant’s capacity.

The project will construct a new membrane bioreactor with treatment capacity of 97 Mega Litres (ML) of wastewater a day, thanks to innovative membrane treatment technology.

The joint venture has committed to implementing a wide range of measures to protect the environment, including:

- using low-carbon concrete blends to reduce carbon emissions;

- reusing 90% of materials on-site;

- supplying its site office with 100% renewable energy;

- using 100% of recycled water for construction activities.

The project is the first in a 10-year program of works and expected to commence in 2025 and to employ up to 250 people at its peak. It will upgrade plant treatment capacity and enhance wastewater services to the Canberra community.

- Design and build of a new household-waste-to-energy plant (79,000 tonnes a year)

- 51 months of works with 200 direct jobs at peak of activity

- Contract worth over €100 million

VINCI Construction through its brand VINCI Environnement (lead contractor) and its subsidiaries GTM Sud- Ouest TP GC and Chantiers Modernes Nouvelle-Aquitaine, has been awarded by Veolia the design and build of a new household-waste-to-energy plant.

Located near Brive-la-Gaillarde, the household waste-to-energy plant will replace the existing plant. It will have a treatment capacity of almost 10 tonnes per hour (79,000 tonnes a year), equivalent to the annual waste produced by 200,000 residents.

This project, worth over €100 million – employing nearly 200 people at peak of its activity – will upgrade the plant’s environmental efficiency by adding latest-generation processing systems, notably to treat flue gases. The electricity and heat produced will be used by local industrial and community facilities.

VINCI Construction’s companies have built solid expertise in waste processing and waste-to-energy systems. In France, they have in particular been involved in the construction or modernisation of waste-toenergy plants in Saint-Ouen-l’Aumône, Saint-Ouen-sur-Seine, Nice, and Ivry-sur-Seine.

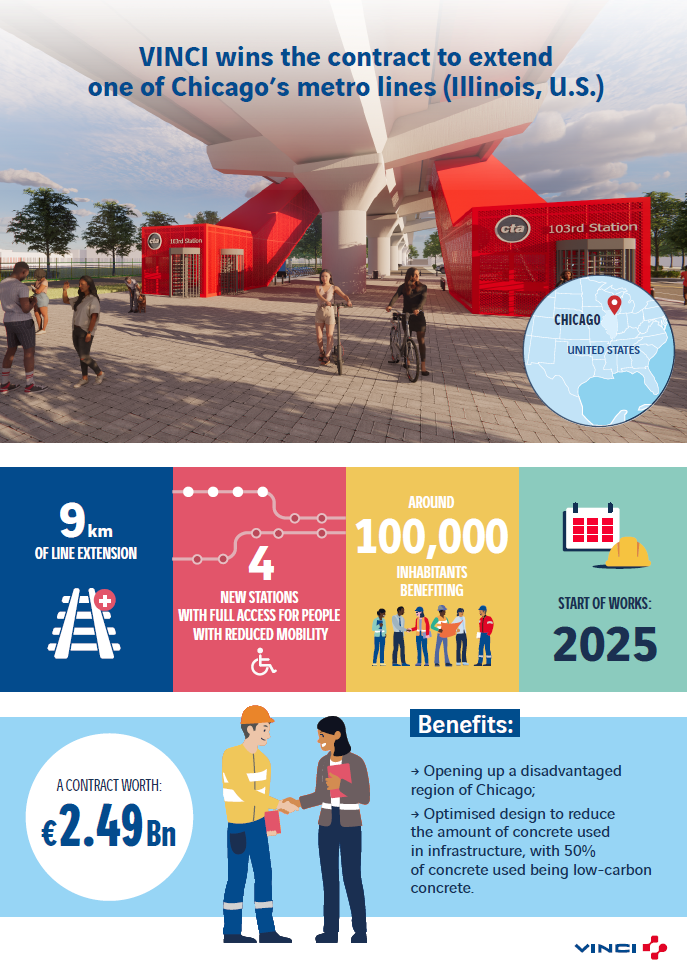

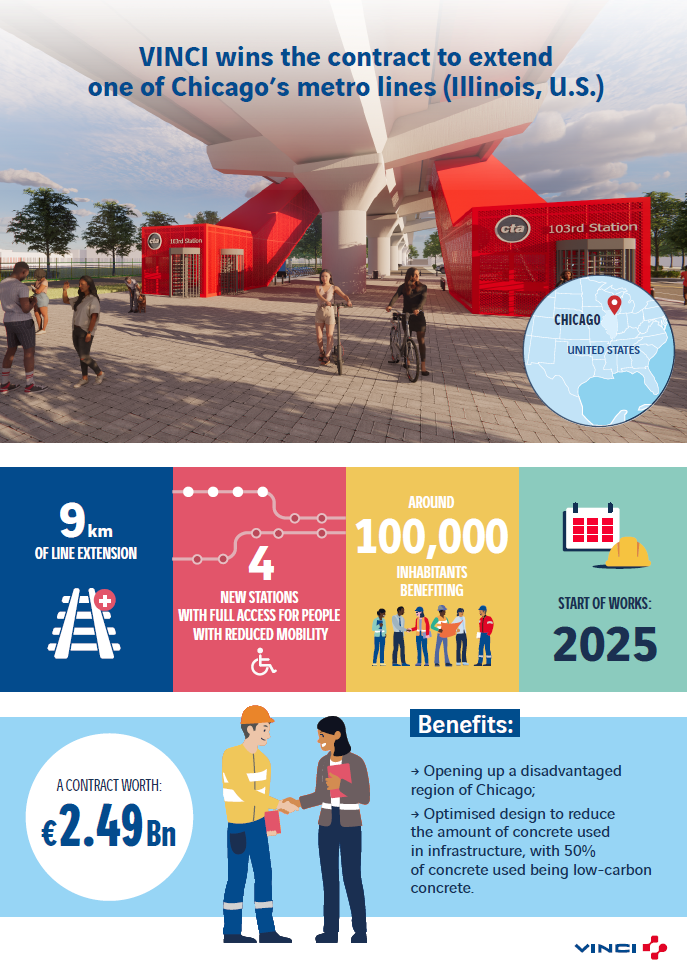

- A contract to design and build a 9 km line extension and four new passenger stations

- A contract worth $2.78 billion (€2.49 billion)

- Ambitious environmental and social commitments

The Chicago Transit Authority has chosen the consortium made up of VINCI Construction Grands Projets (40%) and Chicago-based Walsh Construction Company (60%) to design and build the Red Line extension of the metro.

The contract, worth 2.78 billion dollars (2.49 billion euros), covers the design and construction of 9 km of line extension including 6.4 km of elevated guideway. In addition, four new stations will be built with full access for people with reduced mobility.

This extension is designed to service Chicago’s disadvantaged Far South Side communities.

The group has made ambitious social commitments:

- 10% of the design work hours and 35% of the construction work hours to be allocated to people from economically disadvantaged areas of Chicago;

- 15% of the construction hours being worked by apprentices and trainees;

- a procurement goal that 22% of construction contracts be awarded to Disadvantaged Business Enterprises.

In terms of environmental commitments, the design optimisations proposed by the consortium will reduce the amount of concrete used in the infrastructure by 14%. In addition, 50% of all the concrete used on the project will be low-carbon.

Preparatory works will begin in 2025.

This extension to the Red Line is scheduled to come into service in 2030. About 100,000 additional residents will have access to a low-carbon public transport service, significantly reducing the time they spend travelling to downtown Chicago and beyond. By 2040, the line is expected to carry approximately 40,000 trips per day.

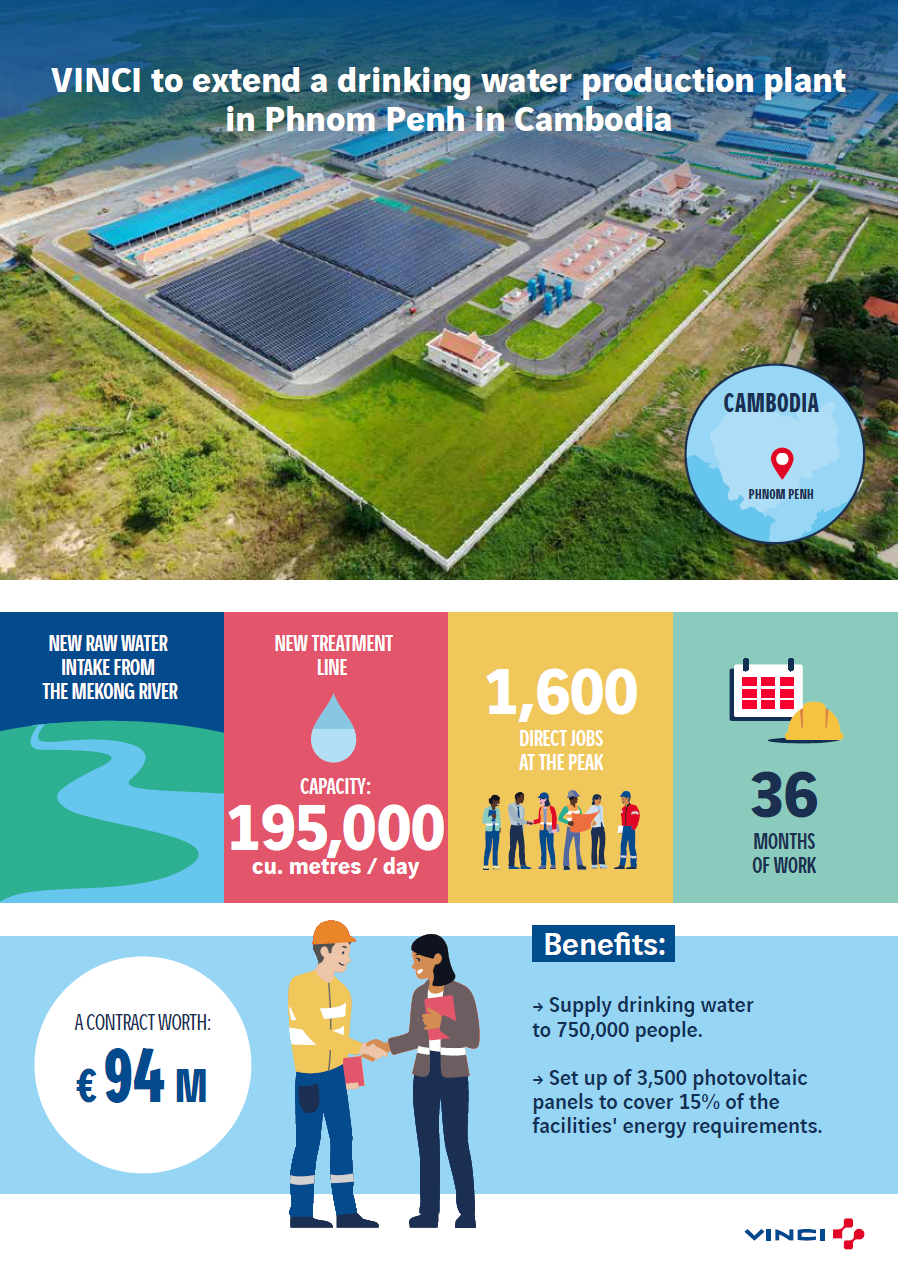

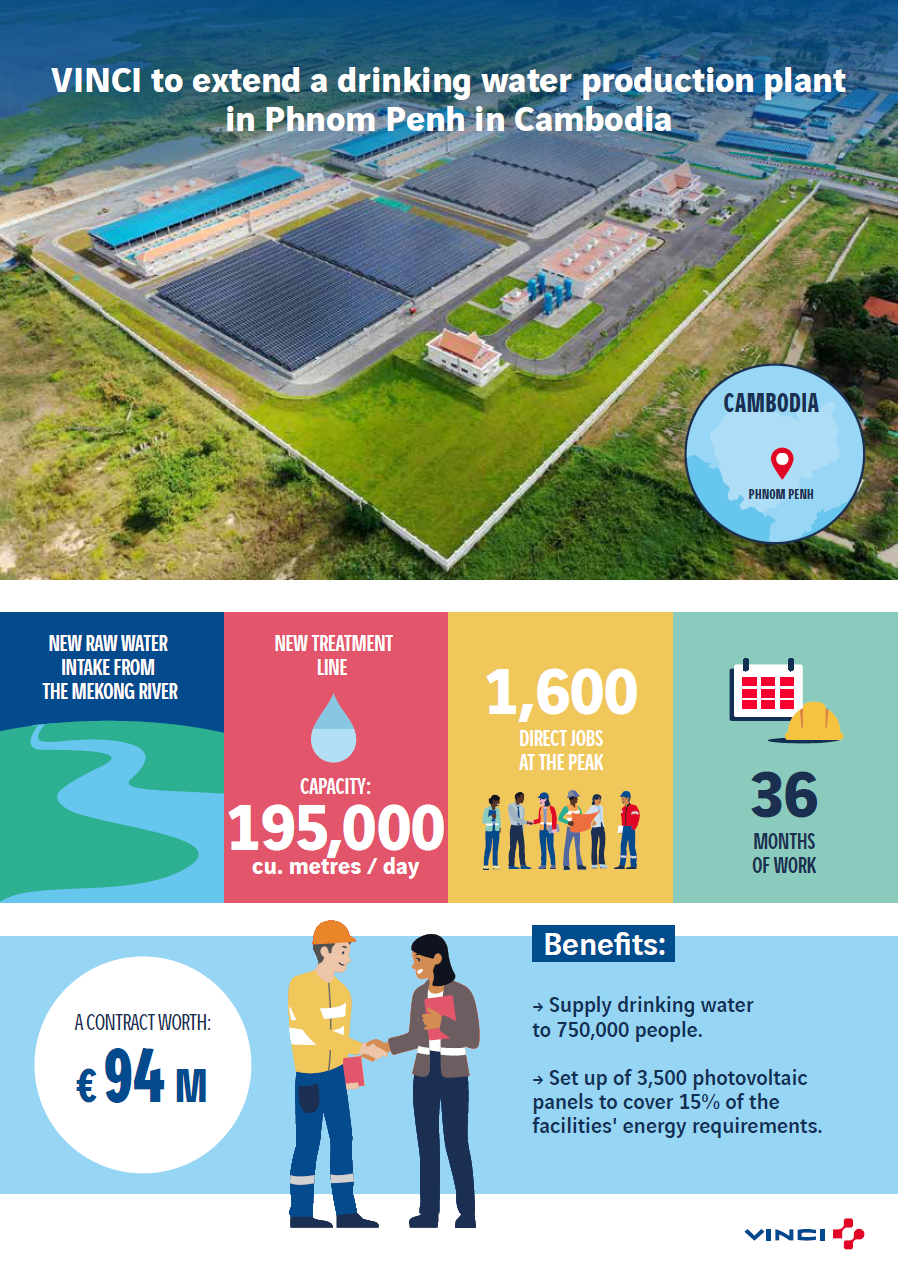

The Phnom Penh Water Supply Authority has awarded VINCI Construction Grands Projets the contract to

extend the drinking water production plant supplying Bakheng, located in the north of Cambodia’s capital.

This €94 million design-build contract covers construction of a new raw water intake from the Mekong river

and a new line with capacity to treat 195,000 cu. metres of water a day.

The construction site will employ 1,600 people at its peak. A large majority of the workers and supervisors

will be Cambodian, women are expected to account for 30% of the workforce, and VINCI Construction

Grands Projets will train them in building trades.

From an environmental perspective, VINCI Construction Grands Projets will:

- use concrete that emits 30% less carbon than standard local equivalents;

- set up a 3,500-panel (9,000 sq. metre photovoltaic array) to cover 15% of the facility’s energy

requirements;

- deploy Smart Users, an innovative solution developed by its subsidiary WMI to measure and manage

water consumption at the worksite and facilities (including offices and concrete plant).

The extension, which is part of the government’s programme to bring drinking water to the country’s entire

population by 2030, will supply 750,000 people living to the north of the capital by 2028. The project will

benefit from VINCI Construction Grands Projets’ expertise in hydraulic infrastructure and its experience

expanding access to water in Cambodia. It follows on from the first two works phases at the same plant, –

which currently supplies water to some two million people – were handed over in June 2023 and March

2024.

After a successful first round, the final ceremony of the Innovation Prize was held on April 4, 2024 in Paris, bringing this 2023/2024 edition to an end.

In November 2023, the Major Projects Division of VINCI Construction launched its first 2023/2024 edition of the Innovation Awards, inviting all its employees to submit innovative projects in 6 themes: Environment, Engineering & Technologies, Health & Safety, Productivity, Management & Human Resources and Marketing & Business Development.

Of the 414 submissions received since last November, 68 had already been awarded within the various entities of the Major Projects Division: each of VINCI Construction Grands Projets’ operational divisions, Dodin Campenon Bernard, VINCI Construction GeoInfrastructure and Spiecapag.

As Patrick KADRI, CEO of the Major Projects Division, said:

“This award is the perfect embodiment of our vision of innovation within the Major Projects Division. Innovation at the service of green and sustainable growth, focused on the future”.

Discover our 9 winning innovations

Environnement – Optimizing and reducing our environmental impact – Project for the underground section of Line 18 of the Grand Paris Express, France

Engineering and Technologies – Linaster – Production monitoring tool and repository for technical project documents, VINCI Construction GeoInfrastructure

Health and safety – Automating and securing lifts in constrained environments – Femernbaelt tunnel project, Denmark

Productivity – Wooden coupler and roller system for pile recutting – Overhead section project of Line 18 of the Grand Paris Express, France

HR Management – Semillero Rosa / Pink Seedbed program – Train 130 women in construction trades and provide them with work experience on our site – Bogotá-Girardot highway widening and modernization project, Colombia

Marketing and Business Development – SMART USERS – Improving management of resource consumption such as water, heating and electricity within facilities – Rennes Airport, France

Jury’s Favourite – Progressive Employment Program (PEP) – Supporting local minorities – Springbank Water Reservoir, Canada and City Rail Link construction projects, New Zealand

Special Award – CONDOR solution – OTool for controlling the use of mobile deck equipment – Initiating Atlantic Bridge project, Panama

Major Prize – EXEGY low-carbon voussoirs – Reducing the carbon footprint of tunnel segments dug with a tunnel boring machine by almost 50%: a world first – Project for the underground section of Line 18 of the Grand Paris Express, France

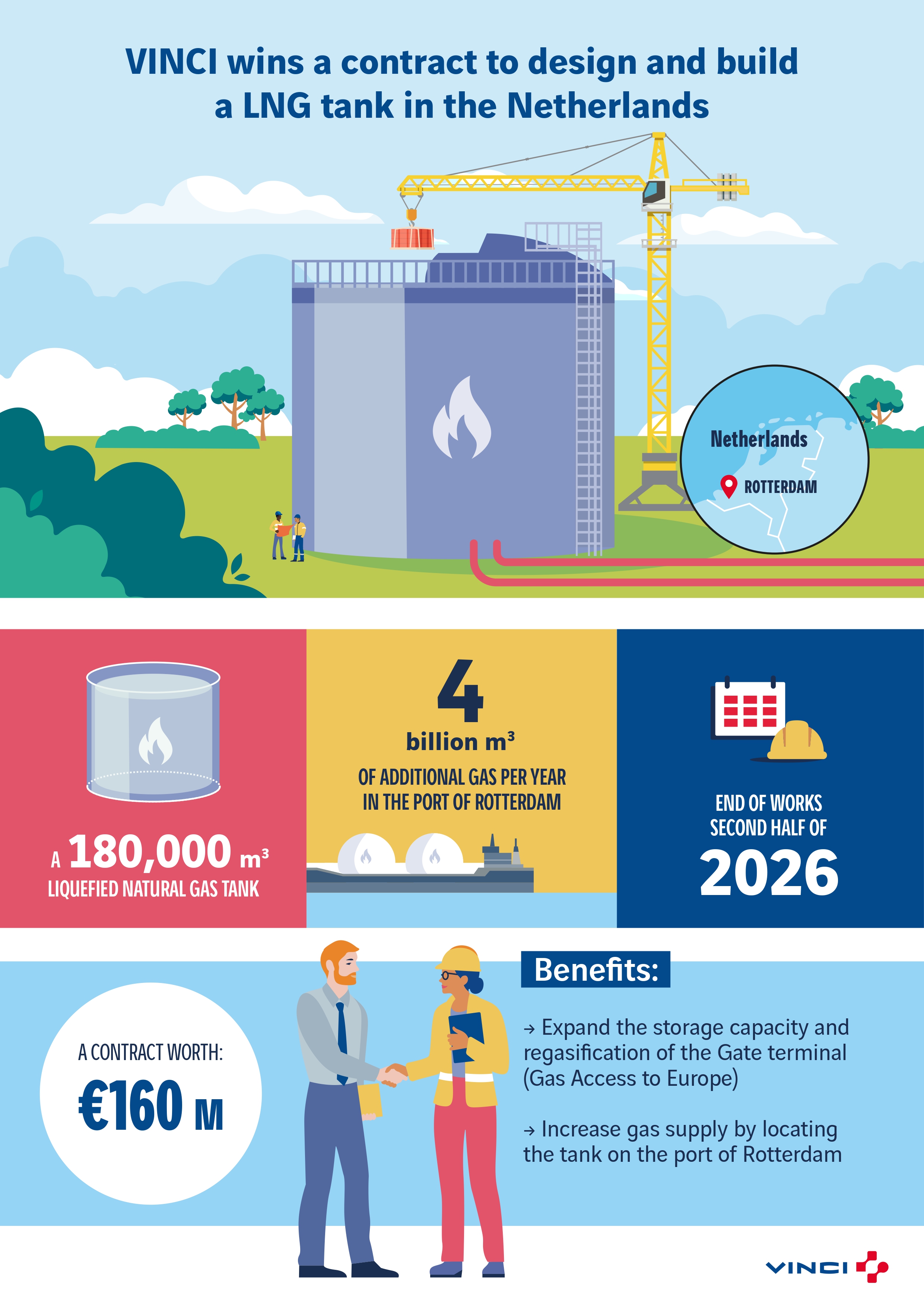

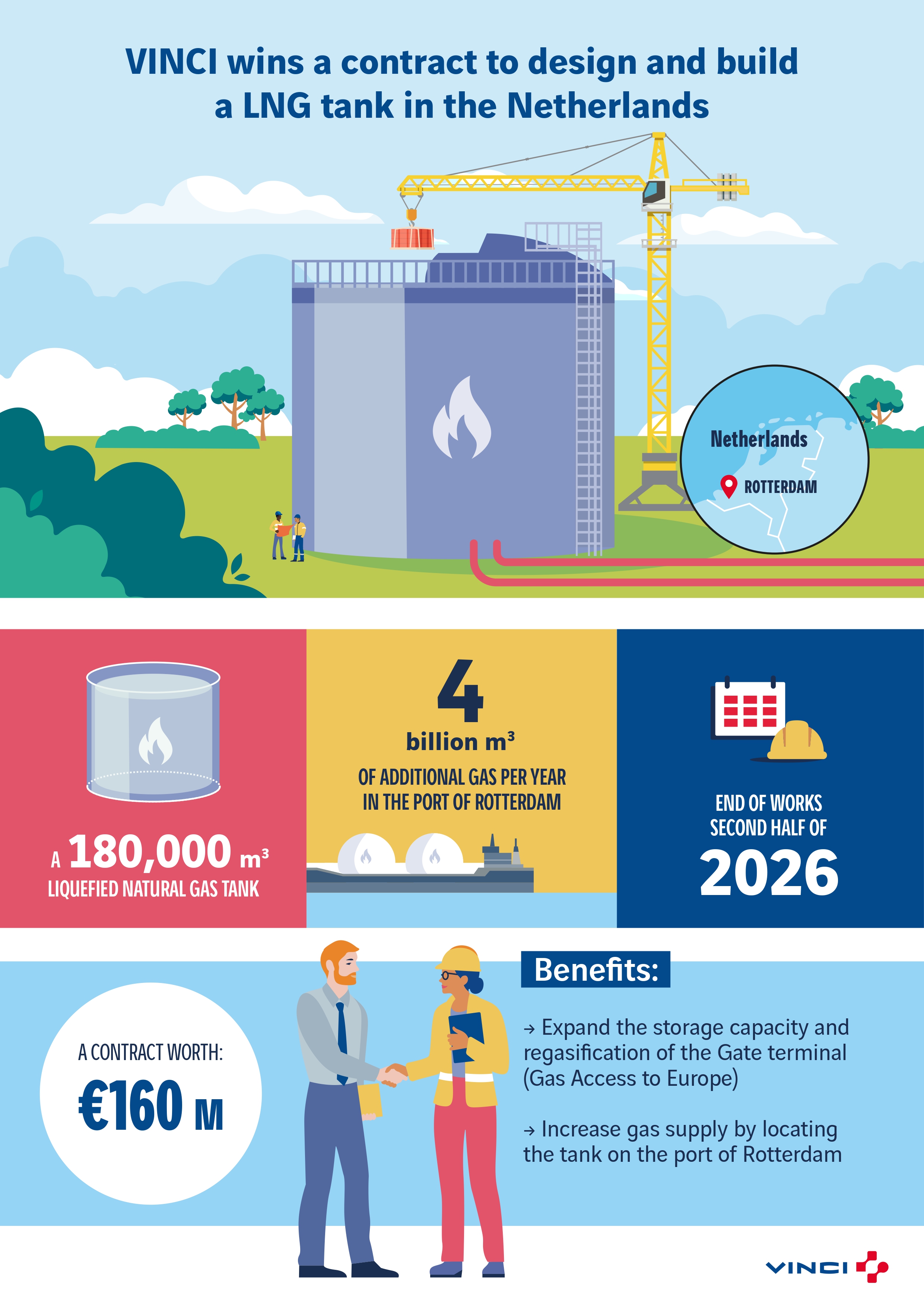

VINCI Construction Grands Projets, a subsidiary of VINCI Construction, have been selected to design and build a 180,000 m3 liquefied natural gas (LNG) tank in the Netherlands. This project falls within the programme to expand the storage capacity and regasification of the GATE (Gas Access To Europe) terminal, based in the port of Rotterdam, by making it possible to supply an additional 4 billion m3 of gas each year.

The project involves the construction of a new 180,000 m3 LNG storage tank with a nickel steel inner tank and a post-tensioned concrete outer container. The contract, worth €160 million, is scheduled for completion by the second half of 2026.

Between 2007 and 2011, VINCI Construction Grands Projets also built three 180,000 m3 LNG storage tanks for this same client, each under design-build contracts.

Having built around 15 LNG tanks around the world over the last decade, including one project still underway in the UK (190,000 m3) and another in Canada (225,000 m3), VINCI is renowned for its ability to meet the expectations of major clients in the industry, working in any type of environment.

Société du Grand Paris has awarded the first design-build contract for the Grand Paris Express to a consortium* encompassing several VINCI Construction and VINCI Energies companies. It covers the first section of Line 15 West. This section, built in a high-density urban area, will link Pont de Sèvres station to La Défense (Hauts-de-Seine – west of Paris).

The contract is worth €2.71 billion and 20% of the works will be entrusted to local SMEs. It covers turnkey engineering and construction of 14 km of tunnels, 5 stations (Saint-Cloud, Rueil-Suresnes Mont-Valérien, Nanterre La Boule, Nanterre La Folie and La Défense), a set of tail tracks and 16 service buildings.

This West section of Line 15 will extend Line 15 South and connect to Transilien Lines L and U at Saint-Cloud and at La Défense, RER Line E at Nanterre La Folie, and RER Lines A and E, metro Line 1 and Transilien tramway Line T2 at La Défense. This section is expected to start operating at end-2031.

Over 2,000 people will work on the project at peak of construction and 10% of the hours of work will be allocated to people on integration programmes throughout the construction period. The consortium has mapped out an ambitious plan to reduce its environmental footprint, alongside Société du Grand Paris: it will for instance mostly use low-carbon and very-low-carbon concrete.

VINCI will involve its Chantiers et Territoires Solidaires endowment fund, which supports non-profits working on public-interest projects aimed at providing job opportunities and fostering social ties in the communities crossed.

Several VINCI Construction and VINCI Energies companies are already active on other Grand Paris Express works packages including Line 15 South between Pont de Sèvres and Noisy-Champs and Line 18 between Orly and Saclay university.

* The Intencités15 consortium brings together construction companies and architecture firms: VINCI Construction subsidiaries (VINCI Construction Grands Projets, leader / Chantiers Modernes Construction / Dodin Campenon Bernard / ETF), VINCI Energies (SDEL Infi), Razel-Bec, Fayat Energie Services, Ingérop, Artelia, JFS Architectes, Grimshaw, AREP Architectes, Archi 5 Prod and Philippe Gazeau Architecte.

Metrolinx, the transit authority for the Greater Toronto region (Ontario, Canada) has awarded VINCI Construction Grands Projets the civil contract for the design-build-finance of a major portion of the new Ontario Line, in a 50/50 joint venture with Ferrovial. The project will form part of the future 15.6 km Ontario Line subway that will run from the Ontario Science Centre to the Exhibition/Ontario Place in Toronto.

The contract, worth CAN$6 billion (€4,4 billion), covers financing, design and construction of the civil engineering, excluding rail equipment, for a 2 x 6 km twin-tube tunnel, together with seven new stations on a general contracting basis. The financing, partly mobilised by the contractor, includes a bank facility mobilising an international pool of eleven banks, including three Canadian. The project will require 89 months of work for delivery in 2030.

The Ontario Line is a major infrastructure project that will reduce congestion, cut travel times and drive sustainable development in the City of Toronto. It will put 227,500 more people within a short walk of transit and accommodate 388,000 daily rides by 2041. It will also significantly relieve congestion on the existing metro line 1, as well as road traffic and the associated greenhouse gas emissions with as many as 28,000 vehicles taken off the roads each day.

The contract allows VINCI Construction, a key player in the construction of mobility infrastructure in North America, to further strengthen its presence in Canada. This new major project highlights its expertise in urban mobility, already demonstrated by its work on the extension of Ottawa’s Confederation Line, which covers design, construction and financing of 27.5 km of new track, 16 stations and the associated engineering structures.

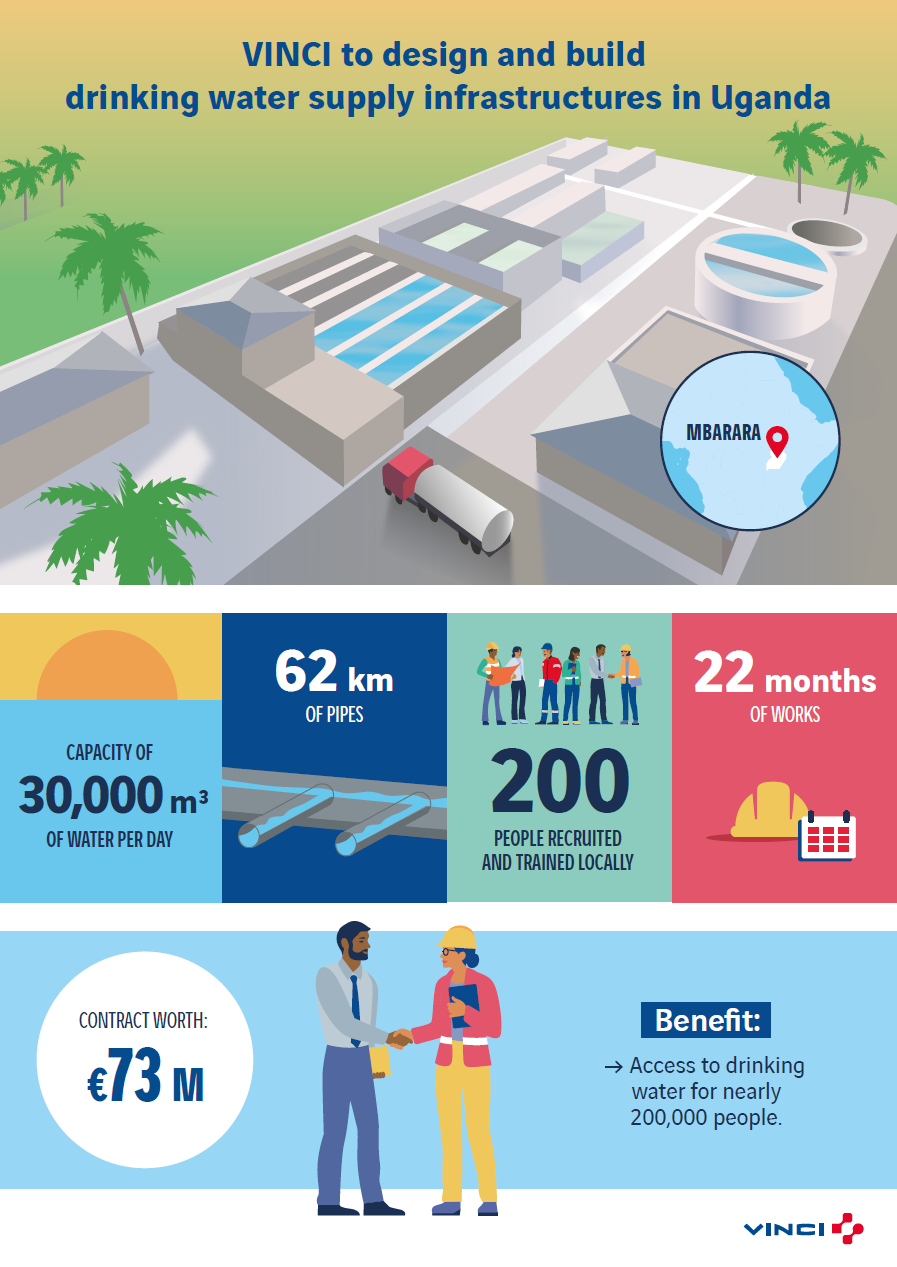

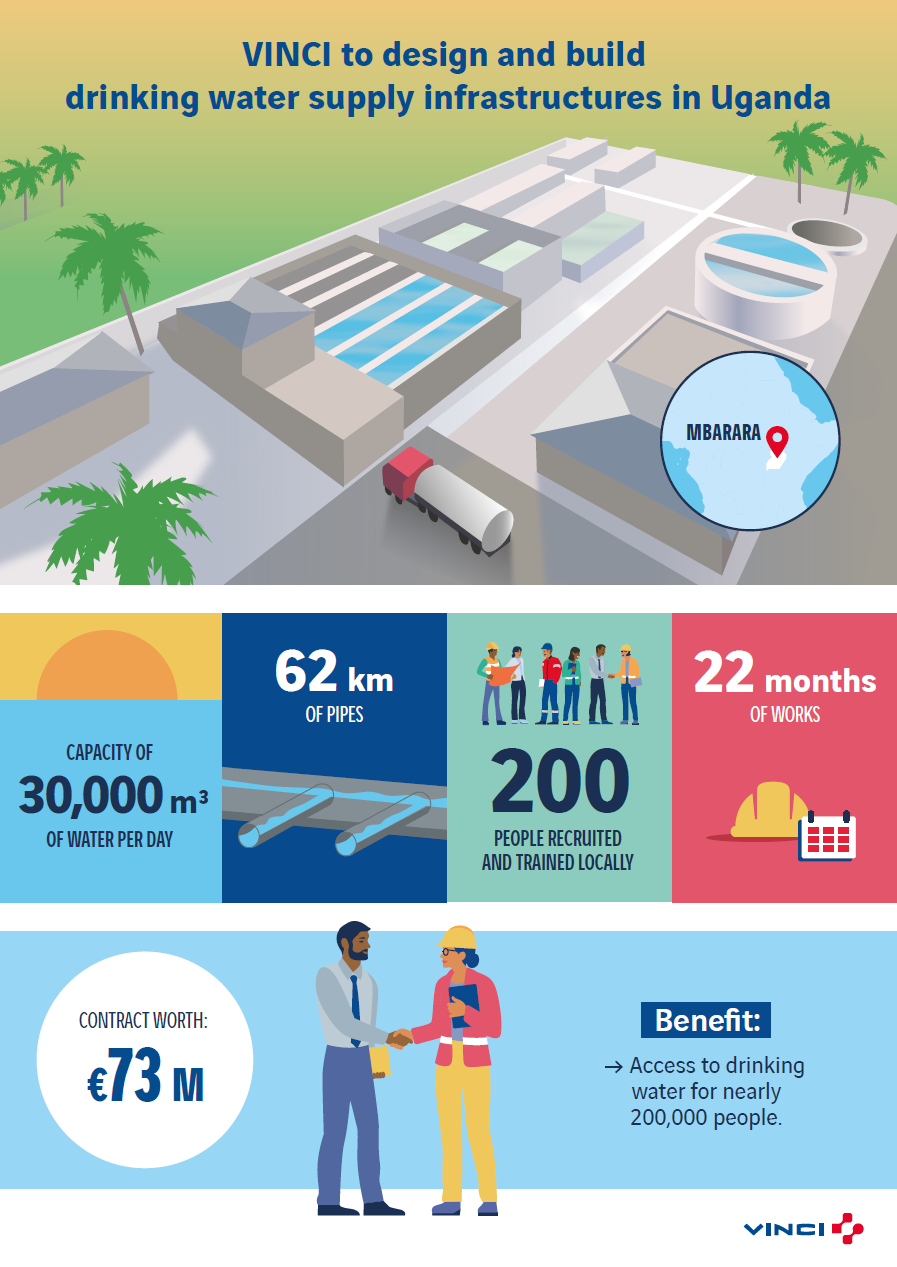

Sogea-Satom and VINCI Construction Grands Projets, subsidiaries of VINCI Construction, have been selected to design and build drinking water supply infrastructure in the Mbarara district of south-west Uganda, on behalf of the state-owned National Water and Sewage Corporation.

This turnkey project worth €73 million, initiated by the Ugandan Ministry of Water and Environment and financed by the French Development Agency, involves the construction of a water intake on the Kagera River, a drinking water treatment plant with a capacity of 30,000 m3 per day, a booster station, and the laying of 62 km of pipes.

200 people recruited locally will be trained in the context of the works, which will last 22 months. Once the installations are commissioned, they will guarantee access to drinking water for nearly 200,000 people.

Sogea-Satom has a long-standing presence in the country, in particular having built the drinking water treatment plants at Ggaba (2016) and Katosi (2019), and having deployed its expertise at the plant at Karuma since August 2021.

Société du Grand Paris and VINCI Construction announce that they are using “voussoirs made of ultra-low-carbon concrete”, which are prefabricated in mechanical moulds, at a Grand Paris Express pilot worksite (Line 18, works package 1).

VINCI Construction started fine-tuning low-carbon concretes for a variety of applications several years ago and has now grouped them together in its Exegy range. After using its breakthroughs in buildings, it has started using them in components such as voussoirs (prefabricated wedge-shaped, compression-assembled parts, to line a tunnel) and pipes for smaller tunnels.

The pilot project on Line 18, which is jointly funded by Société du Grand Paris, is designed to ascertain that the formula with a very low environmental impact works adequately, verify that it can be poured into formwork (casts) at the pace required for an industrial operation, then check the finished product’s behaviour in storage and over time under operating constraints.

An initial phase, which involved testing at CDB, a VINCI Construction subsidiary that specialises in concrete prefabrication, led to a concrete formula suited specifically to voussoirs. The second phase, industrial production at Stradal, the subcontractor selected by VINCI Construction (which has been awarded Line 18 works package 1), began in September 2021. This phase will involve producing five full rings (the equivalent of 40 voussoirs) sized for the project, and the first units will be used for full-scale qualification tests (ISO fire test, load tests).

Replacing conventional concrete voussoirs with Exegy ultra-low-carbon concrete ones and Ecocem Ultra alkali-activated binder has a significant impact on the worksite’s environmental performance: emission reductions amount to about 70% compared to traditional concrete and 50% compared to very-low-carbon concrete (respectively 90?kg of CO² per cu. metre in the case of ultra-low-carbon concrete, 170?kg of CO² in the case of very-low-carbon concrete and 330?kg of CO2 in the case of traditional concrete).

The use of permanent prefabricated voussoirs made of ultra-low-carbon concrete, containing cement-free alkali-activated slag, in a section of a metro tunnel in use, is a world first. It will thus be an opportunity to conduct a benchmark study, in real-life conditions, on the use of a new, greener material in tunnels. Over time, qualification of this type of Exegy voussoirs and the mainstreaming of ultra-low-carbon solutions could bring about a massive drop in the carbon footprint of the tunnels built in France.

A European Technical Assessment to secure approval for the Ecocem Ultra alternative alkali-activated binder has been under way since 2019. Then, concretes containing this binder will be able to earn NF EN 206/CN certification by October 2021. Certification will open the door to using Exegy ultra-low-carbon solutions containing Ecocem Ultra binder for a wide variety of purposes and thus to significantly shrinking the carbon footprint of the concrete poured.

The production of this ultra-low-carbon concrete containing an alkali-activated binder has been patented jointly by VINCI?Construction and Ecocem. VINCI?Construction is working with partner concrete manufacturers to equip them with the know-how to produce Exegy concretes.