BACKGROUND

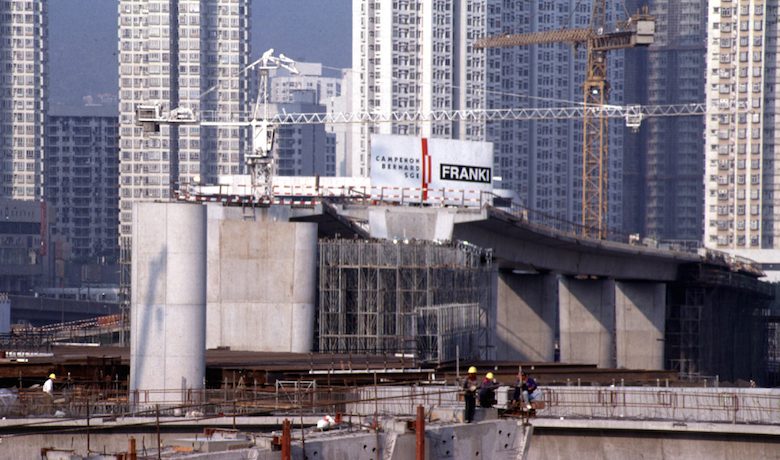

The project to create a link between the new Chek Lap Kok Airport and the city centre in Hong Kong was launched in the late 1980s. In our response to the call for tenders for the construction of the viaduct, we decide to recommend a design variant for the deck of the main structure. In so doing, our objective was to streamline implementation methods while reducing the quantity of required materials – thereby achieving optimal competitiveness. This technical variant earned us the contract. Throughout the project, we used precast segments for the deck and concrete beams to raise the structure above the 15 highway lanes crossing half the length of the worksite.